FOR IMMEDIATE RELEASE

May 3, 2021

For more information please contact:

Zenagui Brahim

President

zenaguib@nhmep.org

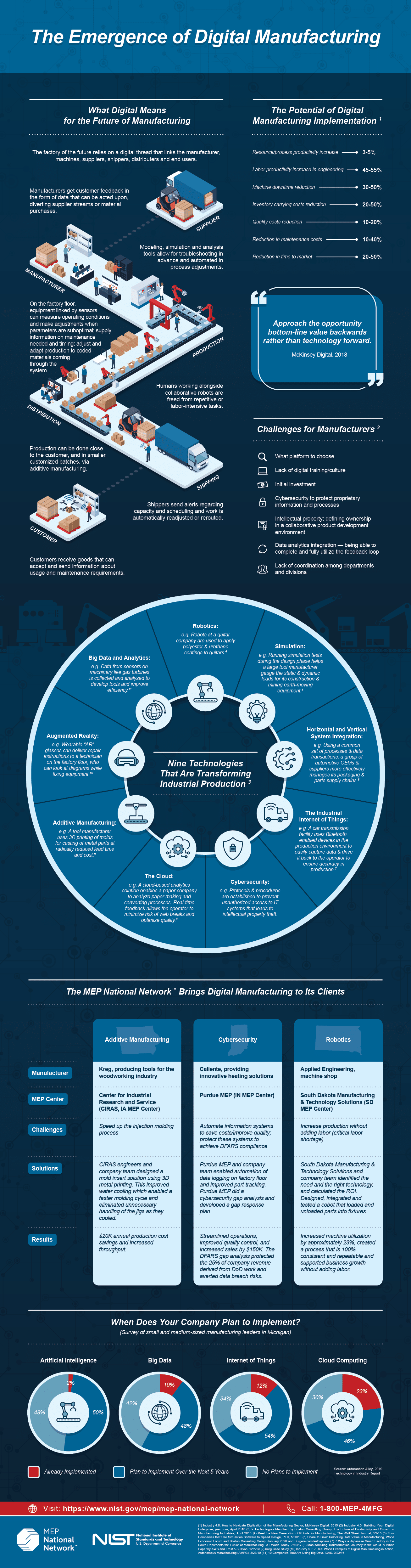

Digital manufacturing is not a new concept but is continuing to evolve. From robotics, additive manufacturing and augmented reality to big data, simulation and cybersecurity, technologies can be found in manufacturing facilities across the country. While already in existence, the use of these technologies among small and medium-sized manufacturers (SMMs) can vary. Some SMMs have already implemented digital manufacturing, while others plan to implement and there are still some that don’t yet see the value of, or intend to, add digital manufacturing technology to their factory floor.

There can be both benefits and challenges for a manufacturer that relies on the digital thread to link their machines, suppliers, shippers, distributers and end users. Challenges may include deciding on what platform to choose, the amount of initial investment required or the lack of coordination among departments and divisions. When these challenges are overcome, manufacturers can see numerous potential rewards such as the reduction of time to market, reduced machine downtime and lower inventory carrying costs.

Not sure where to start when it comes to digital manufacturing? The MEP National NetworkTM has proven success in bringing digital manufacturing to its clients. View the infographic below to learn more or Download the PDF

You can also View our Workshop calendar to register for the latest Industry 4.0 virtual workshops.

About NH MEP

The NH MEP is an affiliate of the National Institute of Standards and Technology (NIST) under the U.S. Department of Commerce. The national MEP system is a network of manufacturing extension centers that provide business and technical assistance to smaller manufacturers in all 50 states, the District of Columbia and Puerto Rico. Through MEP, manufacturers have access to more than 2,000 manufacturing and business “coaches” whose job is to help firms make changes that lead to greater productivity, increased profits and enhanced global competitiveness. For more information please visit www.nhmep.org or call 603-226-3200.