FOR IMMEDIATE RELEASE

February 16, 2021

For more information please contact:

Zenagui Brahim

President, NHMEP

zenaguib@nhmep.org

By Ian Lenahan

news@fosters.com

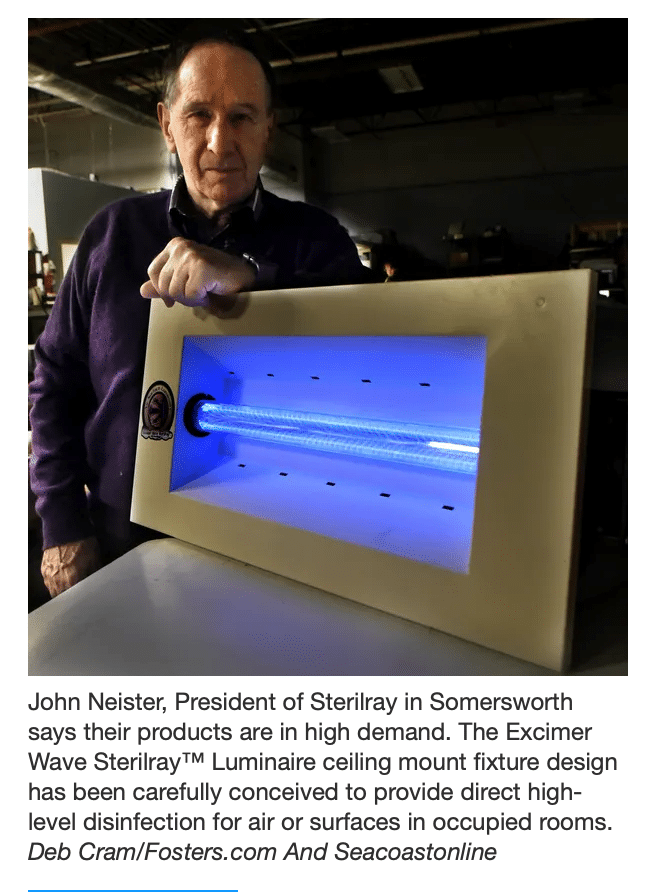

SOMERSWORTH — John Neister, president of Far-UV Sterilray, recalls that five years ago he and his team predicted the disinfection company’s products would be in high demand at the onset of the next pandemic.

“But we never dreamed it would be something like this,” he said.

John’s partner in the Somersworth business is his brother Ed Neister, a physicist who, he said, developed lasers for President Ronald Reagan’s “Star Wars” missile defense initiative in the 1980s. He has also worked on medical lasers for tattoo removals and discovered a high-powered, single-line ultraviolet light wavelength in 1999, according to John.

Ed Neister filed a patent for the 222nm wavelength for air, surface and liquid disinfection in 2005. The 222nm light has higher photon energy than the conventional 254 nm wavelength often found in disinfection equipment that may have detrimental risks to human health, according to John, adding it has been shown to be safe for human exposure.

Founded in 2007 by the Neister brothers, Far-UV Sterilray’s myriad of ultraviolet light-based products have garnered widespread attention as a means of killing virus particles in occupied spaces not only more effectively than higher wavelength technologies, but also in a fraction of the time.

John said that the 222nm wavelength is 10 to 1,000 times more effective than the 254nm wavelength (UVC) due to its intense photon emission: 10 to the 15 power per square centimeter per second. (That is 30,000 times the number of trees on earth). A Far-UV Sterilray™ lamp, he said, “is literally putting out a car wash of photons” in the air and on surfaces.

“So, literally in an eighth of a second, a virus particle coming out of your mouth will be destroyed,” he added.

The 254nm wavelength, John said, alters DNA so it can’t replicate, whereas the Far-UV 222nm wavelength is a “chemical bond breaker” that breaks apart the pathogens.

Far-UV Sterilray™ products are advertised on their website as 1,000 times safer than 254nm wavelength technologies, mercury and ozone free, having over 30,000 hours of lamp life and, above all, a technological feat that destroys coronavirus particles.

“Our goal is to reduce the number of annual superbug and viral infections, reduce the number of patients suffering from these deadly infections, and reduce the burden of the billions of dollars these infections cost our healthcare system every year,” Far-UV Sterilray’s website states.

John said Far-UV Sterilray™ has seen its disinfection technologies come into high demand as COVID-19 rages on, including being contacted by some NFL teams, Boeing manufacturers and robotic disinfection companies specializing in the disinfection of office spaces, military barracks, public transportation and hospitals.

Other notable Far-UV Sterilray™ clients include Canadian-based PCL Construction, Lahey Hospital in Burlington, Massachusetts, and Visby Medical in California.

PCL Construction partnered with Far-UV Sterilray™ to create Pure Portal, a portal of Far-UV light which rids grocery store shopping carts of COVID-19 and other viral particles with four seconds of exposure to Far-UV light at six inches away, according to John.

“Through our validation process, PCL has found that Far-UV Sterilray™ light is exponentially more effective at deactivating 99.9% of pathogens over traditional UV-C methods in a fraction of the time,” a PCL press release said, adding that concept models are being deployed to other parts of Canada and the United States.

All Far-UV Sterilray™ products are manufactured in Somersworth, led by a team of about 20 employees. By the second quarter of 2021, John hopes to see the company’s team grow to between 30-40 employees, and local contracted manufacturers will help with the assembly of products in the future.

Slated to be completed in January, the next generation lamp station in Somersworth-based Far-UV Sterilray™ lamp technology is scheduled to produce 60,000 lamps annually. That represents a drop in the bucket as to demand for millions of these lamps, according to John. “We have several major corporations that are in the process of licensing our technology to build their own lamp stations,” he said.

Sales from the first quarter of this year tallied more than the previous two years combined, he noted.

“Since the pandemic, it’s just gone through the roof as far as interest goes worldwide,” he said.

Far-UV Sterilray™ marketing and sales support specialist Jenny Harper said had the company’s technologies been implemented earlier on, thousands of lives could have been saved.

“If this technology was already in place before the pandemic, we would not have had to shut down our schools, our companies, or small businesses. Families would have been together at hospitals with their loved ones for major surgeries, births, and doctors’ appointments,” she said in a prepared statement. “Production facilities could have been fully staffed. Public transpiration would have been safer. Restaurants could have full capacity again and public events like high school and college graduations wouldn’t have been cancelled.”

John said he left his former career in publishing to complement his brother’s scientific prowess. Fifteen years later, Far-UV Sterilray™ is seeing painstaking efforts pay off.

“It’s gratifying to finally see 15 years of hard work come into the public eye and that we can actually save lives. That’s why Ed and I got into this,” John said.

ABOUT Far-UV Sterilray™

Far-UV Sterilray™ is the world leader and developer of 222nm disinfection equipment. The Company utilizes patented 222nm, Excimer Wave Sterilray™ Technology for its commercialized devices, deployed globally since 2007. Their disinfection products produce a complete kill of bacteria, viruses, molds and fungus in seconds or less by direct impact of a unique photon wavelength. This chemical free technology is safe, environmentally friendly, mercury-free and does not produce ozone. As the sole-source provider and the only company licensed to manufacture these products they have been validated by over 40 third-party lab studies with a greater than 99.99% effective kill rate.

For Inquiries: Far-UV Sterilray™ Phone:(603) 516-2050 http://www.sterilray.com

About NH MEP

New Hampshire Manufacturing Extenship Partnership (NH MEP) is the official representative of the MEP National Network™ and NIST MEP in New Hampshire. The MEP National Network is a unique public-private partnership that delivers comprehensive, proven solutions to U.S. manufacturers, fueling growth and advancing U.S. manufacturing. Through MEP, manufacturers have access to more than 2,000 manufacturing and business “coaches” whose job is to help firms make changes that lead to greater productivity, increased profits and enhanced global competitiveness. For more information please call 603-226-3200 or email Jill Duddy at jilliand@nhmep.org.