FOR IMMEDIATE RELEASE

July 7, 2020

For more information please contact:

Zenagui Brahim

President, NH MEP

603-226-3200

zenaguib@nhmep.org

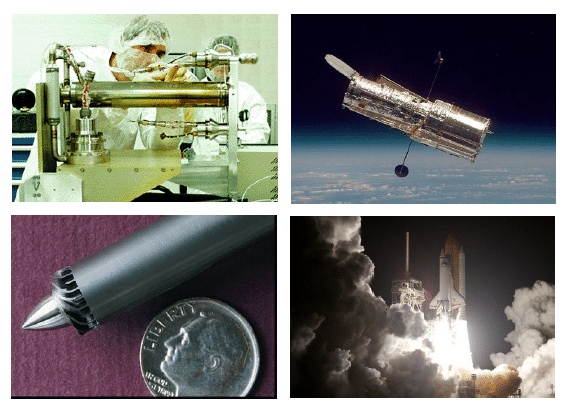

Hanover, NH – Creare LLC, a New Hampshire-based research and development engineering firm, revealed their newest innovative technology to support ongoing and future NASA missions. In addition to their 60,000 sq. ft. of offices and laboratory facilities, Creare works with many small to mid-size New Hampshire manufacturers to develop their products. “Creare’s partnerships with local manufacturers have been vital to the success of our technology in NASA’s and DOD’s space programs,” said Paul Movizzo, Creare’s DoD Business Development Officer. Continuing their space heritage from the Hubble Telescope, Creare has several projects destined to be in space in the near future.

Space Cryocoolers Creare built on years of component and system development when it successfully constructed a cryocooler to extend the life of the Near-Infrared Camera and Multi-Object Spectrometer (NICMOS), a critical instrument on the Hubble Space Telescope (HST). Most recently, Creare’s cryocooler technology is baselined for thermal management of the cryogenic fuels on NASA’s Human Landing System that is part of the Artemis Program. “We are excited by the opportunity to participate in this exciting program and look forward to having our hardware on or orbiting the moon in 2024”, said Mark Zagarola, Creare’s lead space-based, cryocooler principal engineer. Creare also delivered a cryocooler to NASA/GRC for use in ground demonstrations of technologies critical for management of cryogenic propellants, including zero-boil-off cryogen storage, transfer, and liquefaction in space. For future astrophysics missions, Creare plans to leverage recent developments in gas bearing technology and low-temperature alternators to engineer a Turbo-Brayton cryocooler that will provide component cooling with negligible vibration emittance and high efficiency at cryogenic temperatures.

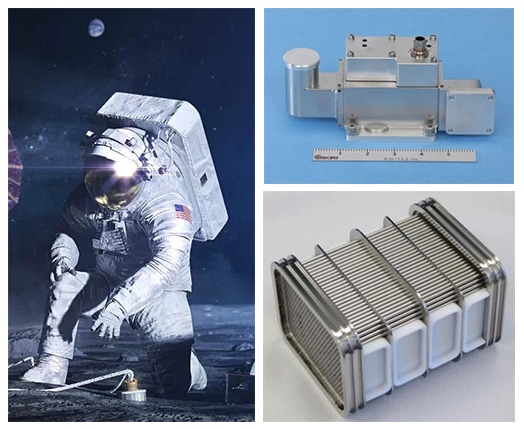

Oxygen cooler and flow meter for the Exploration Space Suit System Creare has developed an innovative flow meter / heat exchanger (FMHX) for use in the portable life support systems that are under development for future space suits. The purpose of the FMHX is to cool the space suit ventilation gas and provide an accurate measurement of the ventilation flow rate. It is a critical system planned for use on Gateway, Moon, and Mars missions. In a project for NASA Johnson Space Center, Creare is designing, building, qualifying, and delivering a prototype for integration with the advanced exploration life support system test bed.

Image by: NASA | Parts pictured above: Oxygen cooler and flow meter for the Exploration Space Suit System

Thermal Storage for High Power Small Satellites Creare is developing an innovative thermal storage technology for small satellite thermal control systems. The technology offers high-energy storage density, excellent thermal conductance, and simple system integration. Thermal storage will enable high-power small satellites to continue using passive thermal control systems instead of active thermal control systems while operating high-power components in variable thermal environments.

Miniature Vacuum Pumps for Interplanetary Exploration Creare capitalized on years of support from NASA and other agencies to build the world’s smallest turbomolecular vacuum pumps, including the pumps sent to Mars in late 2011 on the Curiosity rover. The vacuum pumps are vital to enable NASA’s search for life on other planets. Work is ongoing for the European Space Agency’s ExoMars mission and the NASA Dragonfly mission to Titan https://www.nasa.gov/press-release/nasas-dragonfly-will-fly-around-titan-looking-for-origins-signs-of-life

“Creare is one of the most proactive organizations in new technologies. We are fortunate to have Creare as a member of our manufacturing community and a client of New Hampshire MEP. We wish them success on their NASA projects,” said Zenagui Brahim, President of NH MEP.

For more information, please visit https://www.creare.com/.