NERDIC Industry 4.0 Readiness Ecosystem: Technology Demonstration on Generative Design and Additive Manufacturing

This technology demonstration is part of the NERDIC Industry 4.0 Readiness Ecosystem program for the New England defense supply chain. For more information, please visit ccat.us/NERDIC.

Join us for a virtual presentation on the use and results of generative design and resulting demonstration parts printed by CCAT.

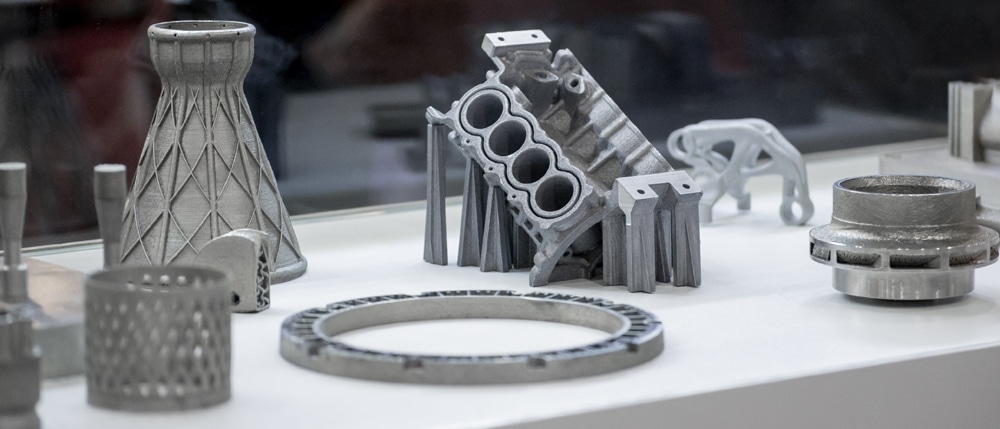

Generative design mimics nature’s evolutionary approach to design. Parameters such as materials, manufacturing methods, strength and thermal requirements are defined, and the AI driven generative design process fully optimizes the design to best fulfill functional requirements.

3D Printing (or Additive Manufacturing) is a powerful tool available to manufacturers. Some companies are adopting the technology to produce end-use parts, but even if your customers are not sending you RFQ’s for additively made parts, most companies can adopt additive to create tools, fixtures, prototypes and other aids to assist traditional manufacturing processes.

This session will be recorded and made available on-demand.

Learning Objectives

By the conclusion of the presentation, attendees will:

• Learn the basics of generative design workflow

• Learn what parameters can be optimized

• Understand how generative design can best leverage additive manufacturing

Presenters

Nasir Mannan, M. Eng., Principal Engineer, Advanced Design, Automation & Metrology Lab, CCAT

Kristi Oki, Mechanical Engineer, Advanced Design, Automation & Metrology Lab, CCAT

Jeff Crandall, Additive Technologies Manager, CCAT

Two introductory workshops precede this demonstration and are scheduled for:

Tuesday, May 4, 2021 @ 12:00 – 1:00 PM EST (1 hour) | Generative Design | Register or view the webinar recording →

Tuesday, May 11, 2021 @ 12:00 – 1:00 PM EST (1 hour) | Additive Manufacturing | Register or view the webinar recording →

For more information, contact Jill Duddy at (603) 226-3200 or jilliand@nhmep.org.