Industry 4.0

Industry 4.0

The Connecticut Center for Advanced Technology, Inc. (CCAT) is excited to launch a series of Industry 4.0 Technology Demonstration Projects. This program will deliver a series of technology workshops and demonstrations to showcase how Industry 4.0 technologies can be used to help optimize manufacturing processes in the New England defense manufacturing supply chain. The technologies include generative design, additive manufacturing, augmented reality, and more. The overall aim is to help increase capability and competitiveness for the region’s defense manufacturers.

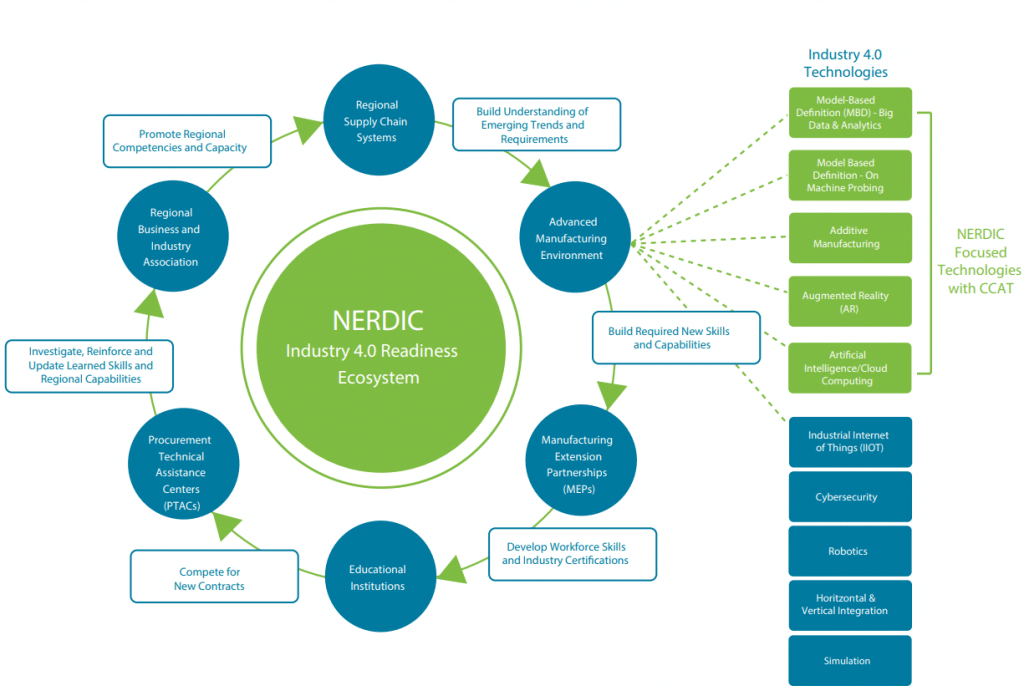

These projects are part of the NERDIC Industry 4.0 Readiness Ecosystem program. This overall program is aiming to help small and midsize businesses meet new cybersecurity requirements for businesses participating in the defense industry supply chain, create an Industry 4.0 ready defense industry supplier network; and build a suitably skilled regional workforce.

About NERDIC

The New England states of Vermont, Connecticut, Maine, Massachusetts, New Hampshire and Rhode Island received a joint grant from the U.S. Department of Defense’s Office of Local Defense Community Cooperation, U.S. Department of Defense (OLDCC), to create The New England Regional Defense Industry Collaboration (NERDIC). The focus and approach of NERDIC is to build regional collaboration and a multidisciplinary approach to supporting the region’s defense industry supply chain. This includes fostering broad partnerships across the regional ecosystem.

Machine Tool Probing for Industry 4.0 – What is it and how does it help your manufacturing process?

Introductory Workshop | June 15 @ 12:00 – 1:00 PM | View Webinar Recording →

Technology Demonstration | July 13 @ 12:00 – 1:00 PM | View Webinar Recording→

Using AI Technology to Crosstrain & Upskill Employees to Support Industry 4.0 Initiatives and Reduce Supply Chain Risk

Introductory Workshop | April 20 | View Webinar Recording →

Technology Demonstration | July 20 @ 12:00 – 1:00 PM | View Webinar Recording →

Augmented Reality for Industry 4.0 – What is it and how does it help your manufacturing process?

Introductory Workshop | April 27 @ 12:00 – 1:00 PM | View Webinar Recording →

Technology Demonstration | July 27 @ 12:00 – 1:00 PM | View Webinar Recording →

Generative Design – An Introduction in Design Optimization to Fully Realize Additive Manufacturing Benefits

Introductory Workshop I | May 4 @ 12:00 – 1:00 PM | View Webinar Recording →

Technology Demonstration I & II | Aug 10 @ 12:00 – 1:30 PM | View Webinar Recording →

Introduction to 3D Printing/Additive Manufacturing to Assist Traditional Manufacturing

Introductory Workshop II | May 11 @ 12:00 – 1:00 PM | View Webinar Recording →

Technology Demonstration I & II | Aug 10 @ 12:00 – 1:30 PM | View Webinar Recording →

Benchmarking 3D Printed Parts Manufactured with the Desktop Metal Studio System for Defense Supply – How can installation, maintenance, upgrades and operator training variables affect quality control?

Introductory Workshop III | May 18 @ 12:00 – 1:00 PM | View Webinar Recording →

Technology Demonstration III | Aug 17 @ 12:00 – 1:30 PM | View Webinar Recording →

Powder Bed Fusion (PBF) and Bound Metal Deposition (BMD) Additive Manufacturing Processes

Introductory Workshop IV| May 25 @ 12:00 – 1:30 PM | View Webinar Recording →

Technology Demonstration IV | Sept 14 @ 12:00 – 1:30 PM | View Webinar Recording →

Industry 4.0 Readiness

The Industry 4.0 Readiness Ecosystem program will highlight technologies in generative design, additive manufacturing, augmented reality, and more. Click on the graphic below to view the full-screen PDF.

New England Manufacturing Extension Partnerships