Blueprint Reading and Engineering Drawing

Blueprint Reading and Engineering Drawing

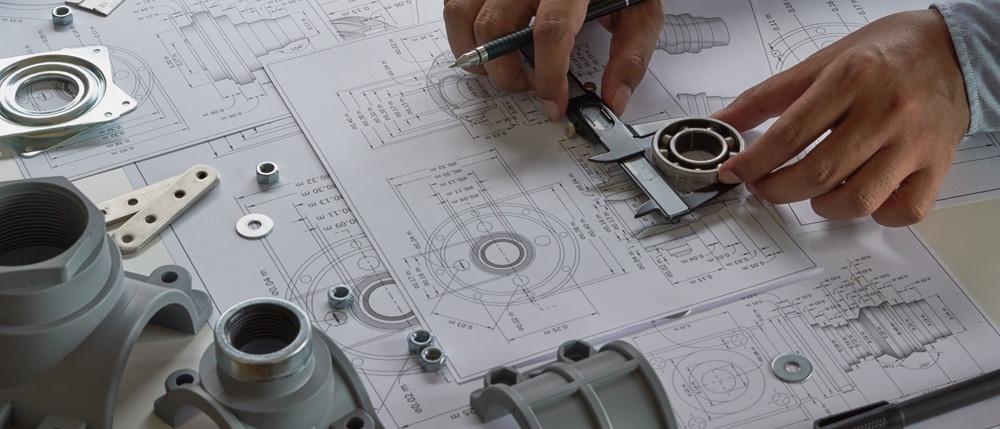

Understanding Engineering Drawings

Course includes Workbook with Reference Guides to Drawing Standards

Event Details:

Students will develop skills to understand engineering drawings, including multi-view drawings, assembly and detailed drawings, section views and auxiliary views. The importance of title blocks, bills of materials, drawings notes and revision control is also emphasized. The course also covers the interpretation of dimensions, surface finishes, screw threads/fasteners, notes and common manufacturing terms and symbols.

In addition, students will be exposed to the basic concepts of geometric dimensioning and tolerancing, with symbols and terms.

Who should attend: Entry-level Quality control and inspection personnel, designers, drafters and machinists; anyone who can benefit from having the ability to understand basic information on an engineering drawing (e.g., sales staff, management)

NOTE: Those with more advanced technical training or experience who need working knowledge to interpret drawings, produce parts or set up measurements of an engineered part or assembly will find the workshops on Geometric Dimensioning and Tolerancing to be more appropriate.

Prerequisites for Blueprint Reading: Basic math: addition, subtraction, multiplication and division. Some prior exposure to engineering drawings helpful.

For more information, call Jill Duddy at (603) 226-3200 or jilliand@nhmep.org.