How can installation, maintenance, upgrades and operator training variables affect quality control?

This introductory workshop is part of the NERDIC Industry 4.0 Readiness Ecosystem program for small manufacturing enterprises in the defense supply chain. For more information, please visit ccat.us/NERDIC.

Learn about what to expect when installing a Desktop Metal System; Overview of install & operations experience, facility, safety & training requirements, vendor support; How the BIC, CCAT and UMaine benchmarked these systems; How to access benchmark files and data; Description of DM case studies underway at BIC; How to access BIC’s facility for training, application development and project collaboration.

Learning Objectives

Learn how Desktop Metal Studio System can be used in defense manufacturing:

- How to prepare your facility, permitting requirements, facility certification options

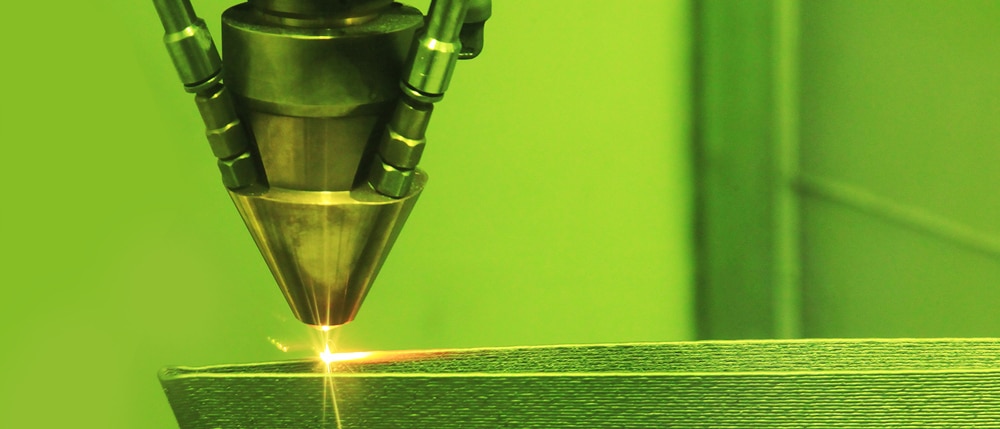

- OSHA training and safety requirements, compared with LPBF, DMLS, LENS and Binder Jetting

- Advantages / disadvantages of printing with bound metal powder compared with LPBF

- Outline applications for DM metal prototypes, fixtures, molds and end use parts

- Review of the design process for benchmarking, developed with CCAT and UMaine – Can the NIST AM Test Artifact be used in FDM metal printing or is a new standard needed?

- Comparison of benchmark results with other 3D printing processes available at CCAT, BIC and UMaine (including LPBF, Binder Jetting, large format polymer FDM and DMLS)

- Can Fused Deposition Modeled Sintered metal parts meet Mil-spec end use requirements?

Presenters

Steven Longpre, CEO BSS Additive, Operations Manager Berkshire Innovation Center

Jean Mozolic, Founder, The Mozolic Group

Mark Rowan, Principal, Roundabout Consulting

Participants will be invited to apply to participate in a pilot demonstration project utilizing this technology. A Technology Demonstration follows this workshop and is scheduled for Tuesday, August 17, 2021 from 12 N – 1:30 pm.

Also, see this link for additional workshops in this series under “Upcoming Events”.

For more information, contact Jill Duddy at (603) 226-3200 or jilliand@nhmep.org.